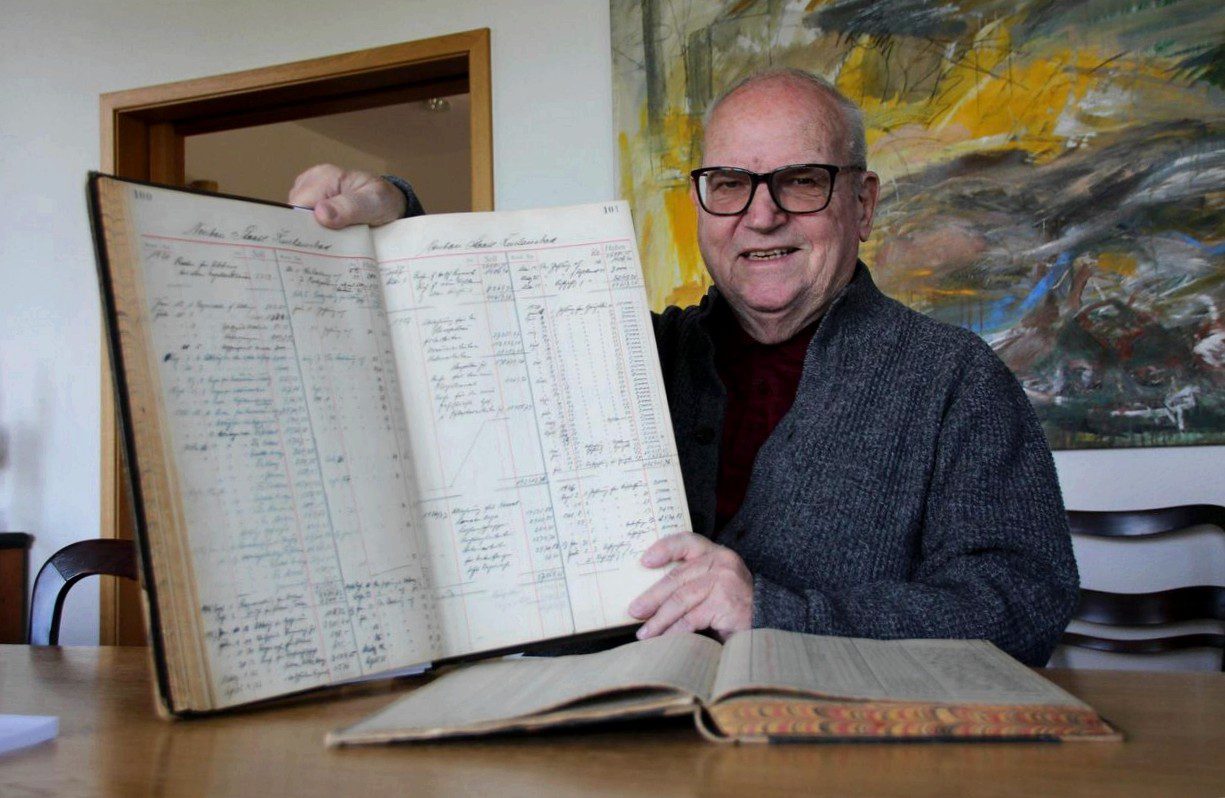

Anton schick senior leafs through an old order book. "New construction of the state spa", his grandfather anton schick (1877 – 1949) wrote above the page header in accurate, neat handwriting. The following are the names of the craftsmen who worked for the schick company in 1926 on what was then the largest spa building in europe. For the company, which was only 22 years old at the time, the state construction project in prinzregentenstrabe was a rough order. "My grandfather visited the construction site every morning", tells schick senior. Armed with his notebook, he talked through the tasks at hand, assigned personnel and organized the supply of materials.

Good contact with max littmann

The grandfather came from the spessart region of germany, from humble beginnings. After his training as a master stonemason in wurzburg, he first worked as a construction manager under the well-known kissingen architect carl krampf. In 1904 he founded his own company, acquired references and built up good relations with the rough munich architect max littmann. He, in turn, was happy to call on schick when it came to constructing the regentenbau and the spa building. "These were the most important construction projects for him. He was very proud of it", says schick senior, who has been running the company since 1965 and still supports his son anton schick junior in the management.

The first invoice in the company archives documents that schick bought the "haus engelhardt" that had previously stood on the site of the kurhausbad has broken off. Littmann had commissioned the bad kissingen construction company with the earthwork, masonry, carpentry and natural stone setting work. "The natural stone base comes from our shell limestone quarry near wirmsthal," reports the 79-year-old, reports the 79-year-old. But it is no longer in operation today.

Dump truck instead of wheelbarrow

The course of the construction has been described in detail in the pictures of the father. You can see an advanced construction site for the time. It already starts with the way the earth was removed from the construction pit. For example, the workers used dump trucks and loaders to load the earth onto the horse-drawn vehicles. "It was progressive because you didn’t have to drive it with a wheelbarrow", explains schick senior. Two cubic meters of earth went on such a horse trailer. By way of comparison: a normal truck can carry ten cubic meters of earth.

Reinforced concrete was used in the spa baths, for example for the spiral staircases. Responsible for this was a company from augsburg. "The stairs were formed on site, reinforced with steel and then poured", says the graduate engineer. Reinforced concrete was still a comparatively new material at that time, on many construction sites the workers had to mix by hand and by mouth. For the kurhausbad, on the other hand, it was produced by machine and the quality was monitored on site.

Schick also mentions another special feature: "unusual was the large proportion of installations for the healing water made from special cast iron pipes." the pipes had to be particularly resistant to corrosion so that they could withstand the aggressive kissinger healing water.